C-profiles, also called C-purlins, are used in many construction projects in the industry, the agricultural and the private sector. The possible applications for C-profiles are numerous and varied. They are mainly used in combination with wall profiles, but these elements are sometimes also used in relation with the roof. To bridge a large distance between wall-spans they can be used and in single-span as well as in multi-span situations. According to the calculated statics, wall distances of up to 10m can be bridged in consideration of wind pressure, wind suction and the height of the building project.

The weight of the purlin is reduced to a minimum due to the filigree cross-section and the high-performance steel used, whereby the weight advantage is noticeable in terms of costs and transport.

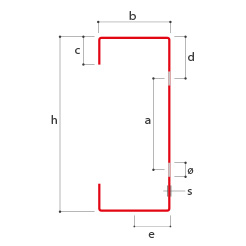

C-profiles produced on roll-formers are only available in certain dimensions, but due to the high production speed they are very cost-effective. Whereas the production of any intermediate size is possible on a bending machine. As a standard, they are available in dimensions from 80 to 300mm height and material thicknesses from 1.5 to a maximum of 4mm. Profiled sheets and sandwich panels can easily be fixed to such C-profiles using self-drilling screws.

STANDARD CHARACTERISTICS OF A ROLL-FORMER

| FEATURES | UNIT | C100-1.5 | C100-2.0 | C100-2.5 |

|---|---|---|---|---|

| STRENGTH (s) | mm | 1.50 | 2.00 | 2.50 |

| WEIGHT | kg | 2.60 | 3.46 | 4.25 |

| e | mm | 18.30 | 18.57 | 18.44 |

| LX | cm⁴ | 55.35 | 70.07 | 88.27 |

| LY | cm⁴ | 13.90 | 16.60 | 19.80 |

| WX | cm³ | 11.14 | 14.01 | 17.65 |

| WY | cm³ | 4.42 | 5.28 | 6.28 |

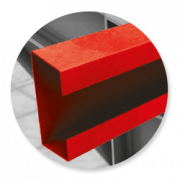

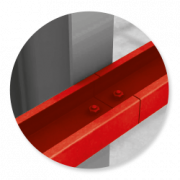

EXAMPLES OF USE